ファルテックとは

ファルテックの強み

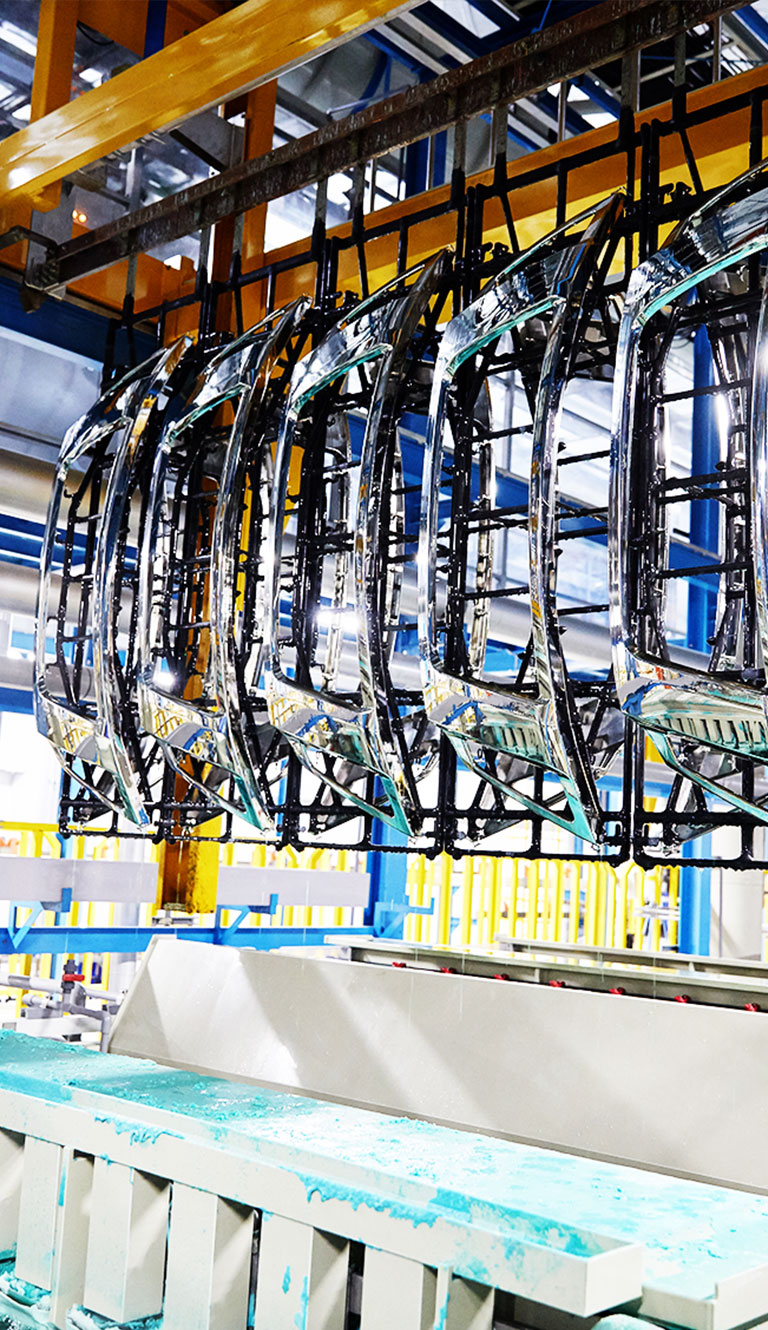

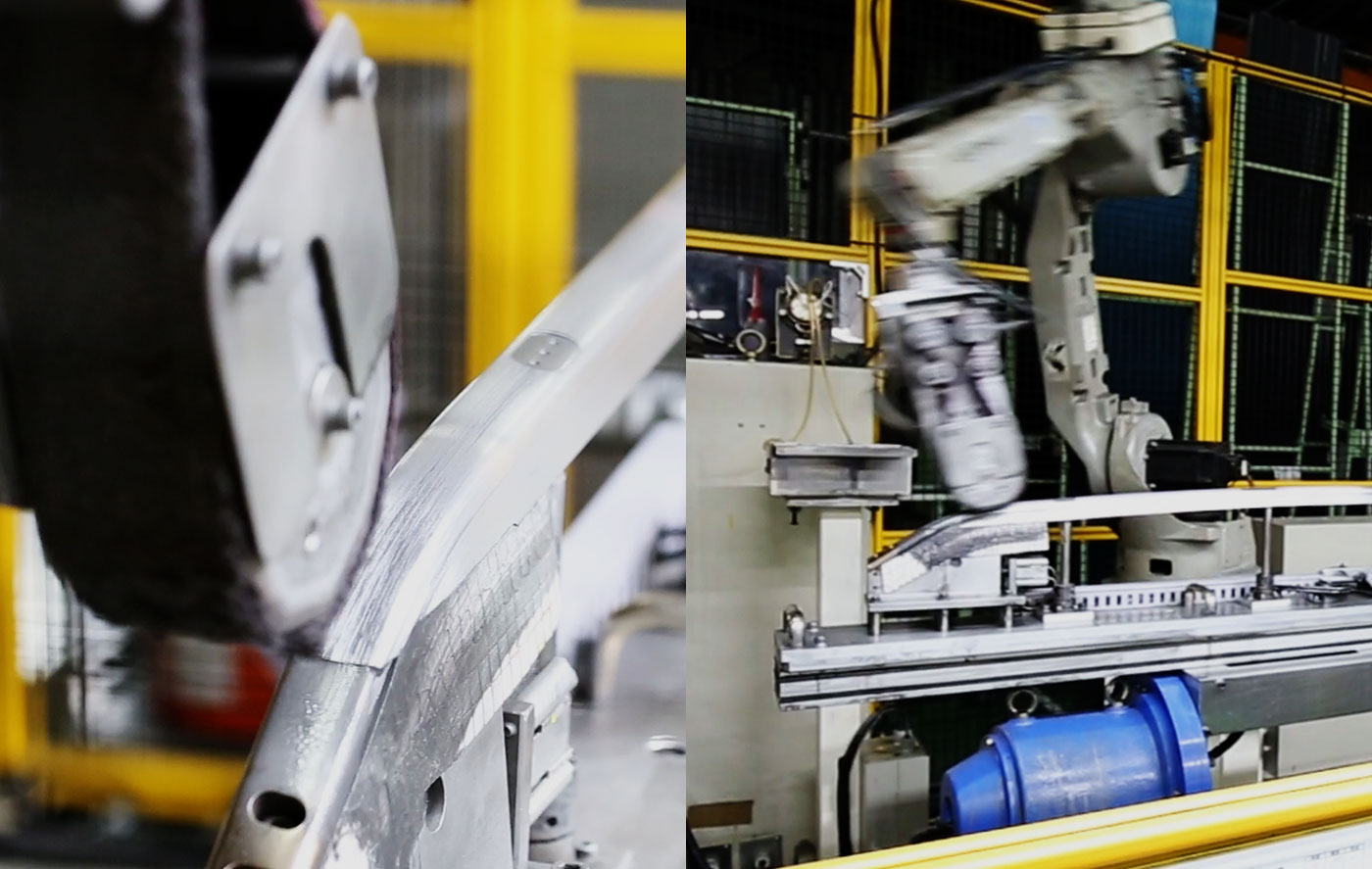

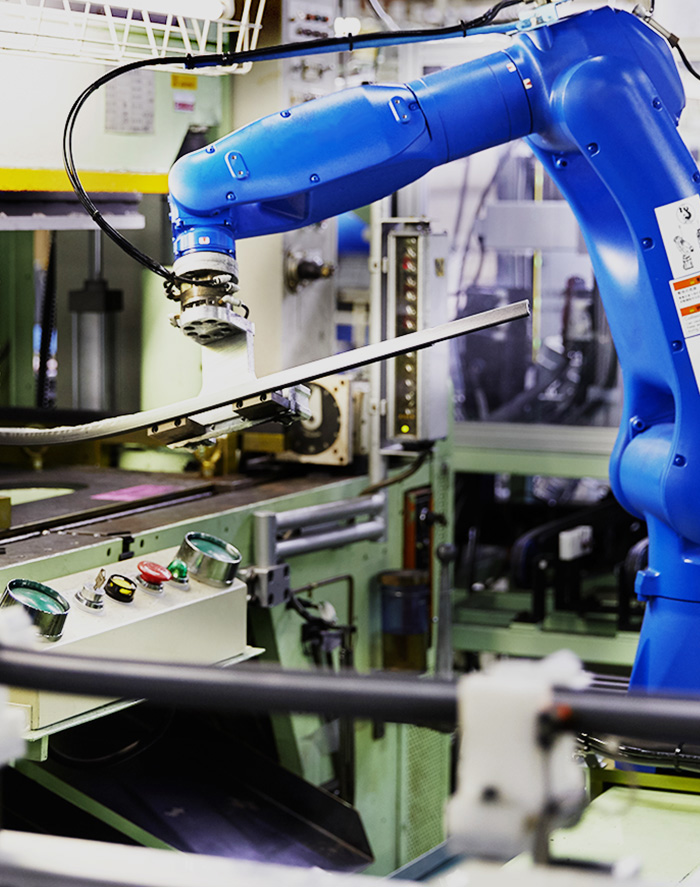

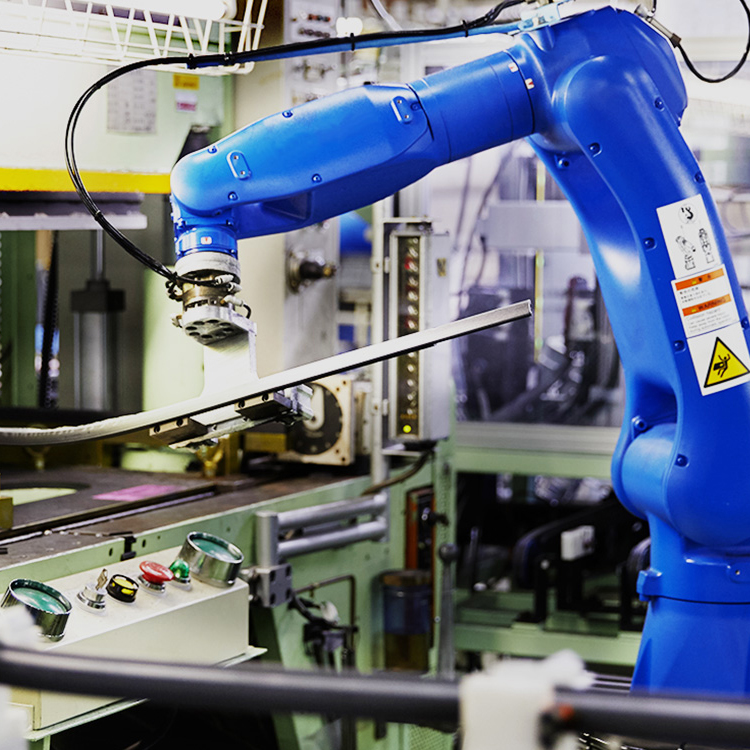

ファルテックならではの技術を活かした外装パーツから、最新エレクトロニクス技術を搭載した電装品モジュールまで、開発環境や生産設備を充実させていくことで、今後の市場をリードする商品をご提供し続けて参ります。

今後ますます需要の高まりが予想されるラジエターグリル・ミリ波レーダーカバー・ルーフレール・ウインドウモール・電装品の5つをファルテック戦略商品と位置付け、集中的にリソースの投入を行っています。